Welcome to what seems to be the final chapter in Suffolk County Council's Upper Orwell Crossings project. This started out in August 2016 as a scheme to build three new bridges across the River Orwell in Ipswich. The original cost estimate was in the region of £97m.

A RIBA-sponsored bridge design competition was held to appoint an architect to work alongside SCC's pre-appointed engineer. This struck me as being:

"one of the worst bridge design competitions to be organised in the UK for quite some time."It turned out that I was not alone in this view. The main criticism was that the contest was an arranged marriage, with SCC picking an architect rather than an architect-engineer team. What if the architect and engineer just didn't get along? The selection process sought and evaluated designs (a total of five designs for three bridges, per entrant, to be precise), but was ostensibly to pick a designer, not a design. It also had a hefty price component, running the risk that a cheap and poor-quality designer could win against a more expensive but higher-quality designer.

A shortlist was announced in October 2016, several of the entrants either bringing along their own engineer or having in-house engineering expertise:

- Adamson Associates (Toronto) with William Matthews Associates and Ney and Partners

- Foster + Partners (London)

- Knight Architects (High Wycombe)

- Marc Mimram (Paris)

- Wilkinson Eyre (London) with FHECOR and EADON Consulting

It was clear from the press statements that SCC had picked what they felt would be a globally-recognised design. I drew attention to the RIBA Competitions office's poor track record at actually delivering bridge designs which went on to be built, and commented:

"Ambition should not be scoffed at, but I do wonder whether Ipswich really needs something world-class, or whether they would have been better to set their sights a little lower."

In April 2018, the Architects' Journal reported on an extensive investigation of the design competition, which showed that the exercise was, at best, poorly conducted, and at worst, actively unfair. There were some serious problems with the quality marking, but it was also reported that Foster and Partners revised and resubmitted their price before being awarded the work.

At this stage, I noted:

"I very much doubt that the designs shown at competition stage will be what is built, and in the absence of any meaningful cost or buildability evaluation, it's entirely possible they are beyond what Suffolk County Council can actually afford."And now this is exactly what has come to pass.

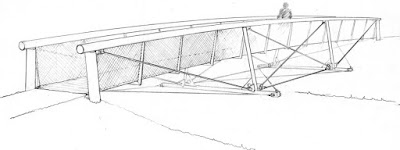

In October 2018, a report was made public from another consultant, Jacobs, employed by SCC to review the project's status and capital cost. According to the latest estimates, the project's budget had increased to somewhere between £122m and £140m. It was apparent that notwithstanding the fuss around the Fosters design, SCC had quietly been developing a secondary design option in the background, a simpler baseline scheme termed by Jacobs the 'Do Minimum' option.

For the main span there was a £10m price difference between the 'Do Minimum' solution (£92m) and the Fosters tree-pier concept (£102m, pictured right). A number of other reasons are cited for cost escalation, none of them amounting to very much other than that the original estimate was too low (figures set before any design was actually undertaken), or that there was a failure to design to the available budget (this may have been impossible anyway).

For the main span there was a £10m price difference between the 'Do Minimum' solution (£92m) and the Fosters tree-pier concept (£102m, pictured right). A number of other reasons are cited for cost escalation, none of them amounting to very much other than that the original estimate was too low (figures set before any design was actually undertaken), or that there was a failure to design to the available budget (this may have been impossible anyway).The problem for SCC is that the project is, in financial terms, highly leveraged (or highly geared). Of the initial cost estimate, only £19m was to be provided by SCC, with the remaining £77m from central government. But central government funds were clearly stated as fixed, so any additional budget has to be provided by SCC. Even if the £122m figure is correct and does not rise further, that leaves SCC having to find £45m - more than double their original commitment, leaving a project they can no longer afford.

This is what also happened in the notorious River Wear Crossing project, eventually killing that scheme, which was also architecturally ambitious, beyond what was reasonable for the site.

Jacobs went on to identify a number of potential cost saving measures, most of them relying on ditching the competition-winning design, and in some options ditching one or both of the two smaller crossings included in the scheme. However, it appears that local politicians have little appetite for the bargain-basement alternatives.

SCC held a cabinet meeting yesterday at which they agreed to cancel the project, although they may still consider whether it makes sense to build only the two smaller bridges.

The papers prepared for SCC's cabinet meeting reveal that SCC have spent some £8.3m getting to this point, the bulk of it (£7.3m) on "external experts and contractors".

This is not quite as bad as the £40m reportedly thrown away on London's Garden Bridge, but you'd hope it's enough for local voters to ask some serious questions of their representatives.