A report

has been published regarding the collapse of the FIU Pedestrian Bridge. The bridge

collapsed on 15th March last year during construction, resulting in six fatalities and several serious injuries.

The report has been prepared by the US

Occupational Health and Safety Administration (OSHA), which I take to be roughly equivalent to the UK's Health and Safety Executive (HSE). A thorough investigation is being carried out by the US National Transportation Safety Board (NTSB), due to be completed later this year, but the OSHA report largely echoes preliminary findings

issued by NTSB last November.

There is no direct equivalent to the NTSB in the UK: we have national bodies for investigating

aviation and

railway accidents, but not for highways, a gap that is long overdue for filling (no doubt, we will have to wait for our own serious incident for this to change, rather than learning from elsewhere).

The bridge was a highly unusual design, comprising two concrete truss spans, each with a single truss along the centre-line of the bridge deck. A pylon and steel pipe stays above the trusses were arranged to give the impression of a cable-stayed bridge, but were largely decorative, with the only reported structural purpose being to reduce pedestrian-induced vibration in the main structural elements. I

discussed the design in more detail in March 2018.

OSHA's report into what went wrong appears detailed and thorough, but some caveats are in order.

The report does not hesitate to apportion blame, stating that the designer (Figg), design peer reviewer (Louis Berger, performing an independent check of the entire design), the construction engineer and inspector (BPA, acting as FIU's representative), and the contractor (Munilla Construction Management, MCM) all failed in their duties and missed opportunities to prevent the collapse.

Oddly, less blame is attributed by OSHA to the highway authority who allowed the bridge to be built above live traffic (Florida Department of Transportation, FDOT). I've

commented on this previously: in the UK and in some other jurisdictions, a highway authority would undertake a process of technical approval for any new bridge built over or under their infrastructure, to protect their own interests which include both avoiding undue impact on traffic, and protecting the safety of highway users.

FDOT took some interest in the project, having their in-house structural engineering group review the designs, and they were represented at regular site meetings including a fateful meeting on the morning of the collapse. Like all the other participants, FDOT's representative missed the opportunity to call a halt to activity on site, but oddly, this is omitted from the report’s executive summary. It is also left unclear whether FDOT were aware of or agreed to gaps in the scope of the independent peer reviewer, who reportedly did not check the bridge in any construction stages, only in its final state.

OSHA appear to have had extensive access to evidence from before and after the bridge collapse, but their report shows only limited sign of having talked to the main participants. Allegations are made, but any responses received are absent. Figg have rapidly gone on record to

criticise the report, stating that they are prevented from saying more publicly while the NTSB investigation continues.

So take anything that follows with a pinch of salt – despite the report's impression of thoroughness, it may be partial and unfair. We'll have to wait until later this year to see what the NTSB have to say.

OSHA start by repeatedly drawing attention to the fact that the bridge was expected to be an aesthetically attractive landmark structure. No connection to the collapse is made explicit, but they seem to want to create the impression that the circumstances of procurement contributed to failure. Otherwise, why mention the topic? Personally, I think the FIU were entitled to rely upon the professional integrity and judgement of their various advisers and contractors, and cannot be blamed for wanting a nice bridge.

The main truss span was cast off-site in four stages on a falsework assembly, before being picked up by a self-propelled modular transporter (SPMT), driven to site, and then set down on its final supports.

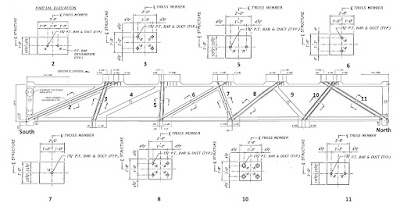

Prior to the SPMT stage, all truss members which would experience tension either during construction or in service were prestressed using stressing bars. Most stressing bars were grouted in, except for the two end diagonals (truss members 2 and 11), as these required prestress to be adjusted during construction.

The first sign of trouble came when the temporary falsework was removed, leaving the truss span supported on temporary trestles at each end. Operatives reported hearing a

"loud popping sound", and soon discovered cracks at the bases of diagonals 2 and 11, where they connect to the bridge's lower deck slab. In this configuration, the end diagonals were in compression, so any prestress applied should have been minimal. Photographs of the cracks were shared with the designer, who OSHA state showed no real concern. The image on the right shows one of the larger cracks at this stage, at the bottom of diagonal 11.

Over a week later, the structure was transferred from the temporary end supports onto the SPMT ready for transport to site. The SPMT carried the bridge on the lower truss nodes one bay in from the end supports. At this stage, diagonals 2 and 11 would have been in tension, and prestressing would have been required. Once placed on the permanent supports, the intention was then to de-stress the bars in these members.

According to the OSHA report, no further cracks appeared and the initial cracks did not develop further during transportation and installation of the truss span. Member 2 was then de-stressed without incident, but further signs of trouble emerged rapidly during de-stressing of member 11. Multiple cracks appeared at the lower node of this member, leading one prestressing operative to report that

"it cracked like hell".

Two days later, pictures of the cracks were sent to the designer for comment. Construction operatives later stated that the cracks had already grown larger, and photographs taken at this stage appear quite alarming in what they show, with evidence that the truss node was separating from the lower slab. Nonetheless, the designer stated that

"this is not a safety issue", proposing that member 11 be re-stressed to return it to its previous state. The designer did not plan to attend site during this operation.

Photographs of the cracks taken over the next two days look steadily more alarming. A key meeting was held 5 days after installation, attended by FIU, the designer, contractor, construction inspector, and FDOT. The designer had now inspected the cracks (which continued to grow) in person, but stated that there was still no safety concern.

Nonetheless, they emphasised the need to proceed with construction of the second span (which, when made continuous with the first span, would reduce loads on member 11), and stated that they would examine methods by which the progressively cracking node could be "captured" or "restrained". According to OSHA, no reference was made back to the peer reviewer at any stage.

On the face of it, the recommendation to re-stress diagonal 11 was very strange. The stressing bars were provided for the temporary condition when the bridge was supported on an SPMT, a situation which no longer existed. Once the bridge was erected on the permanent supports, re-stressing the diagonal added to load in the diagonal and its connecting nodes, rather than reducing it.

Re-stressing commenced as instructed, and was nearly complete when the bridge collapsed.

OSHA describe the failure as a "concrete blow-out", but an appropriate term for it is a shear or punching shear failure: the upper part of the truss node sheared clear out of the lower deck slab, partially along the lines of construction joints created during the original phased construction pour.

The image below shows the node after failure, looking towards the end of the deck. The large empty pocket was originally solid concrete; the rough area in the centre of the bottom edge of the photo was originally where the truss diagonal connected into the deck. The various vertical ducts appear to be for lighting cables or similar.

The next photo shows the same area looking straight onto the end face of the deck slab after it was removed from the collapse site. The empty pocket at the top is the same empty pocket visible in the previous image.

The cracks observed prior to failure are consistent with this, including longitudinal splitting seen on diagonal 11, which was presumably caused by the longitudinal movement of the bottom node, splitting occurring due to the different anchoring positions of the upper and lower stressing bars within the concrete.

With the node destroyed, the truss was no longer fully triangulated at all points, and the full load of the bridge could only be carried by bending of the top or bottom truss members (the roof canopy and the deck slab), a condition which neither member could ever have been designed for. This is precisely what is meant when the design is described as lacking redundancy – there was no secondary load path. In addition, there was limited ductility – shear failure can occur much more suddenly than a bending failure.

Here is the node detail as shown in the OSHA report, viewed from the side – the position of the construction joint is not clear but the report states elsewhere that the truss diagonals and verticals were cast after the deck slab, so the joint runs horizontally somewhere through the middle of the diagram.

OSHA's calculations show that the combined capacity of reinforcing bars crossing the construction joint, plus friction caused by the vertical component of axial load in diagonal 11, were insufficient (in accordance with the design codes) to resist the horizontal component of axial load in diagonal 11: the shear demand was calculated to be 22% higher than the shear capacity. Re-stressing the bars made the situation worse, with demand then 45% higher than capacity. I have some diagrams below which perhaps make this clearer.

The potential punching shear failure is shown in this diagram in the OSHA report, viewing the node from above with the force from member 11 acting towards the bottom of the diagram:

The report doesn't spell out why failure did not occur when the truss was first landed on its permanent supports: the loads and prestress state at this time were the same as immediately prior to the actual failure.

The progressive nature of the cracking may be relevant here: the re-stressing was applied to a structure which had already severely fractured, showing evidence of slip along the shear planes of the construction joints. In this situation, resistance would have been greatly reduced below what the design code suggests. The fracturing and slip itself may have been caused by an initial failure of the concrete surface upon installation, with the progressive cracking then caused by plastic deformation of the reinforcing bars passing across the joint.

The visible evidence of the punching shear failure also indicates the failure to have been 3-dimensional and the 2-d drawing of the node is therefore misleading. What particularly bothers me about the node detail is that it is highly unclear how the compression in diagonal 11 is transferred into the tension system of the post-tensioned bridge deck. The OSHA report draws attention to this, and it seems to be the case that a lack of adequate provision to transfer these forces laterally from the plane of the truss into the plane of the deck contributed to the failure.

In the OSHA analysis, the truss node was therefore under-designed for the loads it had to carry; it had not been checked in this condition by the independent checker (who reportedly considered only the final situation once the two spans were made continuous); and there was no redundancy in the design, such that if any one truss member failed, bridge collapse was inevitable. To add to the bridge's vulnerability, vertical ducts were located either side of the node, potentially weakening the whole area – these are visible in one of the photographs included above.

It may be partial at this stage, but the picture that OSHA sets out is consistent and compelling.

Their report is lacking in diagrams which clearly show the lines of force, the positions of the cracks, and the eventual failure, so I've had a go.

The first diagram shows the compression in diagonal 11 (red), which can be resolved into a vertical compression force and a horizontal shear force where the diagonal connects to the deck (both in grey), with the horizontal force balanced by tension in the deck (blue).

The second diagram shows the position of cracks visible prior to failure (yellow), and the direction of movement of the upper part of the node corresponding to these cracks (white).

The final diagram shows very roughly the planes along which the concrete failed to cause collapse. On the left hand edge of the section highlighted in black, a block of concrete punched clean out, while on the right hand edge of the same area, failure was in pure shear through a construction joint between the diagonal and the deck.

Note that the construction drawing shows shear reinforcement passing through that part of the construction joint – failed reinforcement can be seen in some of the OSHA photographs. The report doesn't state the diameter of these bars, but from the photographs they appear to be very small compared to other visible reinforcement.

OSHA concludes (a) that the truss node was under-designed for the forces it had to carry, and (b) that a series of competent professionals failed to take adequate precautions when clear evidence of problems with the structure came to light. OSHA addresses the "what", but not the "why".

I think speculation should be limited and those involved should have the opportunity to explain their actions and identify any flaws in OSHA's argument. However, I think there are a number of questions which should be asked:

- How did the agency responsible for highway safety ensure that an acceptable process was in place for design and construction, and did they review or agree any of the methods of design to be used, especially for critical or unusual details? In the UK, the design methodology would be presented in advance through a Technical Approval process, reviewed and accepted by the relevant infrastructure authority. This process was introduced into the industry following notorious bridge failures in the 1970s. Do the US authorities apply anything similar, and if not, is there a failure to learn from international experience?

- Who determined and who accepted the peer reviewer's scope? This was an unusual design, with significant changes in load at different construction stages, yet apparently the peer reviewer entirely ignored key construction stages, including the stage where collapse occurred. Why was this not part of their scope?

- What calculations did the designer undertake? Were key calculations missed, or incorrect, and if so, what errors were made? The OSHA report presents the conclusions of the agency's own calculations but says nothing about what the designer actually did or why in their view the node design was adequate.

- Given the structure's clear lack of redundancy, how did the designer conceptualise critical details? Were simple shear rules applied or were complex details such as the node modelled in more detail? I would have expected a finite element model of a detail like this, unless simple calculations showed it to be highly robust.

- Why did the designer state that the cracking was not a safety issue? With hindsight, it seems clear that a serious developing failure should have been apparent, with the cracking demonstrating insufficient strength. It should also have been clear that once the concrete cracked in the manner it did, the strength of the node was immediately reduced.

- Was it reasonable for the other project participants to rely entirely on the designer's advice? OSHA's view is that they did not act reasonably – that they had sufficient expertise to stop work until further precautions were in place. I'm far from convinced about that: the designer was clearly the structural engineering expert and from one perspective it's hardly unexpected for others to defer to that.

- What external pressures existed, relating to cost or programme, or to a desire not to disrupt traffic further?

- Was this the most appropriate design, particularly with the choice of materials? It seems difficult to believe that this failure would have occurred in a steel truss design.

OSHA's report is very direct and reductive in its analysis of failure. The truss node failed in punching shear. The designed capacity of the node to resist this failure mode was inadequate. The designer, and everyone else involved in the project, failed to recognise the seriousness of the initial cracking. Nobody took any steps to prevent the cracking from progressing, or to safeguard highway traffic. The action taken, re-stressing the prestress bars, made things worse rather than better.

This is a clear causal chain, and in the

Swiss cheese model of systemic failure, all the holes in the various layers of cheese lined up. However, I'm not convinced that it is sufficient simply to identify human error: mistakes are inevitable, and those responsible for the system should put in place mechanisms both to identify error (such as independent checking), and to minimise its impacts (such as adoption of robust materials and structural forms).

If the OSHA report is accurate, then serious issues are apparent, and from conversations with others in the industry, these issues are not unique to the FIU pedestrian bridge project. Some of the key issues appear to be behavioural: reliance on advice without challenge; the assumption that competent people do everything right; a reluctance to take the evidence of today and imagine what it will result in tomorrow; the suggestion that because an occurrence is not yet explained, no action should be taken.

Many of these can be attributed to cognitive biases and even if they were found not to have caused the failure of the FIU bridge, those involved in other projects should still reflect on their own safety culture, the way in which teams respond when challenged, and what can be done to ensure appropriate behaviours are rewarded rather than discouraged. Engineers should also reflect on whether the divisions of responsibility in their technical governance and assurance processes are fit for purpose. Given that errors will occur on some project at some time, what are we doing to prevent them resulting in catastrophic outcomes?

My experience is that structural engineers are often prone to simply following normal process, standards and methods. Risk assessment too often concentrates on construction and operational hazards or even just on commercial risks. It is rare to see a structural engineering plan of work arising directly from a meaningful analysis of the risks of structural failure: often, it's just assumed that codes and standards are sufficient to address those particular risks. The best way to work out how to make a structure stand up is first to work out how it would fall down, a lesson that could have been learned from many disasters but is still not embedded properly in regular practice.